E-mail: info@plywoodworking.com Phone: +8615854986399

E-mail: info@plywoodworking.com Phone: +8615854986399

Specification

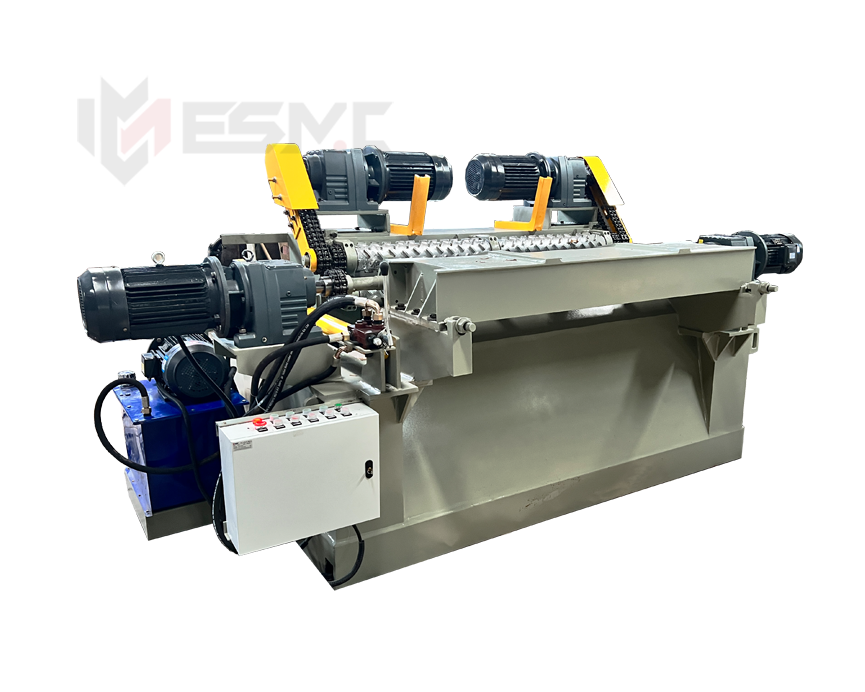

MODEL: ES150ZY-60

Log Diameter: 50-600 mm

Log Length.Max.: 1500 mm

Rub Roller Diameter: 178, 178 mm

Single Roller Power: 7.5kw

Double Roller Power: 11kw

Hydraulic System Power: 5.5 kw

Wood waste chipping function: CHOOSE

Engineered for professional woodworking and plywood working operations, our spindle-less debarker and rounder features:

Weight-enhanced base (20% heavier than standard ordinary models) for vibration-free and stable operation.

Customized roller design with wolf-tooth pattern grains or gear type roller for faster bark stripping.

Hydraulic pressure adjustment system for customized processing.

Extra-wide opening capacity handles larger diameter over 500/600mm logs efficiently.

Creates perfectly round logs ready for downstream processing.

Both machines are built with:

✓ Higher-grade components for extended service life.

✓ Low-maintenance designs requiring minimal downtime for years using.

✓ Safety-enhanced operation features with covers for chains.

✓ Compatibility with most wood species even with 2 end big and small diameters logs.

Applications: Veneer production, sawmills, furniture manufacturing, and timber processing operations seeking to improve yield and product quality.

Please feel free to contact for the heavy duty log Debarking and Rounding machine from 4ft to 10 ft with different models. We will try best make the good and stable veneer plywoodworking machine to you. And offer the full term after sale service. ESMC appreciate your support and trust.

After Sale :

Pre-sale services:

1) Free consult to help you choose suitable veneer making or plywoodworking machine.

2) Base on your production improvement or equipment upgrading needs, make full set plywood,veneer production solutions. and offer the machine drawings.

3) Offer detail machine technical parameters and quotations, after confirm each other, sign the PO or invoice.

4) Invite customers to visit workshops and test plywood machine working.

Services during the sales:

1) Updating the machinery manufacturing process.

2) Strict inspection of machine quality during each manufacture and assemble process and detail tesing before delivery.

3) Free training the machine operating and using, make the user manual help customer comand the skills.

4) Confirm the custom clearance documents and prepare delivery.

After sale services:

1) 7/24 hours engineer ready to service to solve problems.

2) Full life spare parts and online machine debugging supporting.

3) Professional engineers installing and trainning service.

4) overseas service of machine upgrading and maintance.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

woodmachine@hotmail.com

Address:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.