Specification

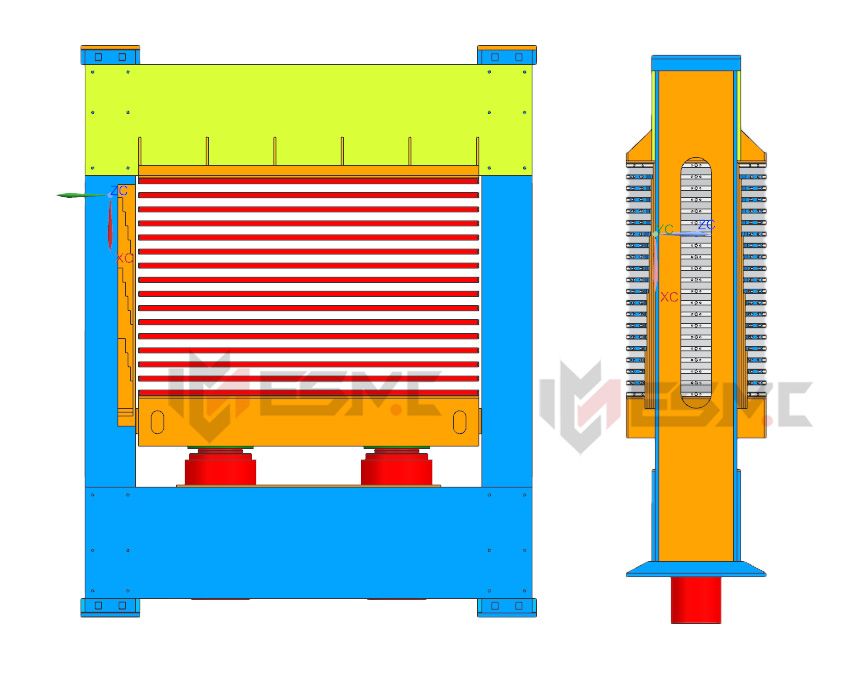

MODEL: ESM-H500/4X8

Pressure: 500-800 T

Hot Platen: 52 mm

Layer Qty.: 15

Working Size: 4*8 ft

Closing Time: 15 second (adjustable)

Working Method: auto/manual switch

This Hydraulic auto hot pressing machine focus on different kinds construction,furniture,LVL plywood making, wooden flooring plywood working. Smooth and stable high temperature heating and high pressure treatment so that to keep the the molding process well working, with the help of quality adhesive glue finally come into the customer satisfied all kinds wood-based panels,plywood board.

Fous on all kinds plywood board, LVL board, film face laminating board making. Full set plywood making , production line equipment.

Customzing and designing according to your products. And offer you suitable technical parameters plywood working hot press.

Customer plywood working production.

Suits all kinds base plywood, construction plywood board, furniture plywood board, melamine paper or other film faced laminating panels.

Full set plywood making machine and matched auxiliary tools and spare parts.

Please feel free to contact for the hot press, cold press, laminating hot press machine. We will try best make the good and stable veneer plywoodworking machine to you. And offer the full term after sale service. ESMC appreciate your support and trust.

After Sale :

Pre-sale services:

1) Free consult to help you choose suitable veneer making or plywoodworking machine.

2) Base on your production improvement or equipment upgrading needs, make full set plywood,veneer production solutions. and offer the machine drawings.

3) Offer detail machine technical parameters and quotations, after confirm each other, sign the PO or invoice.

4) Invite customers to visit workshops and test plywood machine working.

Services during the sales:

1) Updating the machinery manufacturing process.

2) Strict inspection of machine quality during each manufacture and assemble process and detail tesing before delivery.

3) Free training the machine operating and using, make the user manual help customer comand the skills.

4) Confirm the custom clearance documents and prepare delivery.

After sale services:

1) 7/24 hours engineer ready to service to solve problems.

2) Full life spare parts and online machine debugging supporting.

3) Professional engineers installing and trainning service.

4) overseas service of machine upgrading and maintance.

Mobile/whatsapp:

+8615854986399

E-mail:

info@plywoodworking.com

sales@plywoodworking.com

ADD:

No.100 Lingong Road, Comprehensive Bonded Zone, Linyi,Shandong,China.